Tips on Tool Tracking and Management

Enhanced visibility and operational oversight of your tool inventory, allowing tools to move fluidly from warehouse to field, or from person to person. That’s smarter tool tracking.

#1 Tool Tracking Tip: Keep it simple!

Tool tracking doesn’t have to be hard. With ShareMyToolbox you can Improve your tool inventory management in three steps.

But don’t let our simple approach fool you. We have all the powerful features you’re looking for in a modern tool tracking and asset management solution. Continue exploring to learn more…

Smarter Tool Management

from Warehouse to Jobsite and Beyond.

ShareMyToolbox works seamlessly in real-time across your PC, Mac, iPad, iPhone, and Android devices.

Unlimited Tools. Unlimited Support.

As part of your subscription we provide seamless cloud hosting. No server software to install. This allows ShareMyToolbox to connect your field users to the office, providing mobile tool tracking without changing your current network setup. Plus, you get unlimited tools allowing you to grow and flex as you need. Simply sign in and get to work. And if you need help, we’re real people here to pick up the phone and chat.

Here’s How It Works

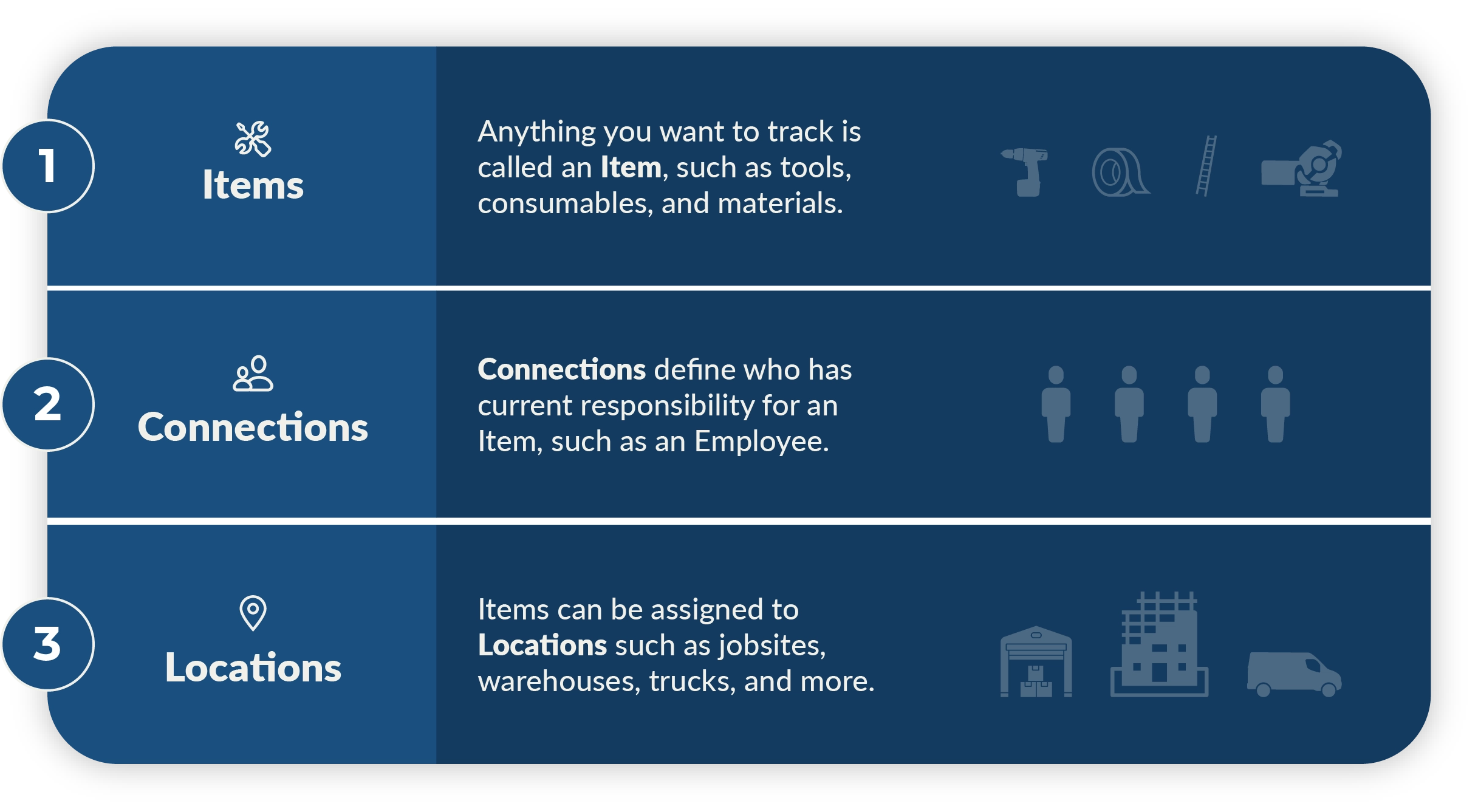

ShareMyToolbox keeps it simple by focusing on the three most important aspects of small tool tracking.

With workflows, It’s all about taking action for seamless transfer and movement of assets.

With ShareMyToolbox, you can use asset tags with QR codes or barcodes, and we even offer a way to tag GPS coordinates each time your Item moves.

Power Users Welcome

Unlock the potential of our Enterprise Web Portal, empowering power users with features like Mass Transfers and robust reporting tools.

Power Tools For Power Users

From enhancing safety and prolonging tool lifespan through service reminder alerts, maintenance record-keeping, costing and billing and more, ShareMyToolbox makes it easy to streamline your workflow while driving profitability, productivity and accountability.